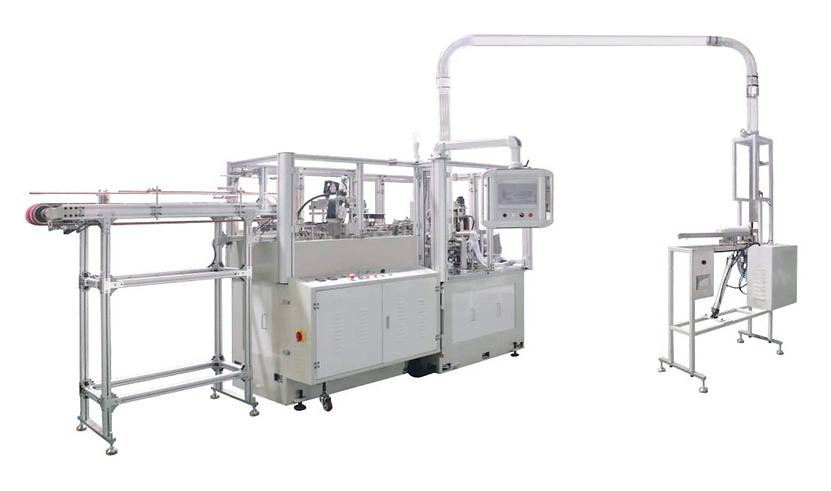

Equipment for manufacture of cup double walls with an option to use recycled cardboard or PE-coated cardboard — is an automated machine that performs the entire process of paper feeding, jointing and joint gluing, formation of the double wall on a cardboard or plastic cup, and assembly of finished products.

Technical specifications:

Capacity of the cup manufactured, ounce: 6-22

Range of the material used, g/m2: 135-450

Gluing method: ultrasound, thermal adhesive gluing (optional)

Power: 10kW, 380V/220V,60Hz/50Hz

Air consumption: 0.4 m3/minute 0.5mPa

Weight: 3 tonnes

Machine dimensions, mm: 2500х1800х1700

Dimensions of the cup assembling machine, mm: 900х900х1760

Output rate, pcs/minute: 80-110

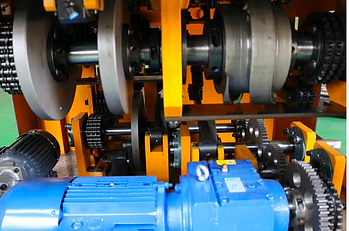

All major components used in this equipment are manufactured by well-known and reliable world manufactures, Panasonic, Siemens, Mitsubishi, etc.

Model |

SMD-80A |

Country |

| PLC/Servo motor |

MITSUBISHI |

Japan |

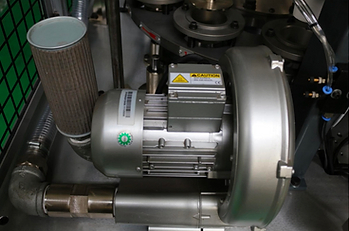

| Hot air system |

LEISTER/BANKO |

Switzerland/CHINA |

| Transducer |

PANASONIC |

Japan |

| Contactor/Button |

SHLINORDE |

France |

| Relay |

IDEC |

Japan |

| Temperature controller |

AUTONICS |

Korea |

| Encoder |

AUTONICS |

Korea |

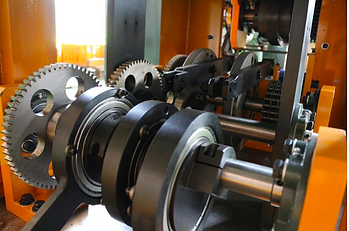

| Needle bearing |

IKO |

Japan |

| Ultrasonic |

EVENGREEN |

Taiwan |

| Touch panel |

WEINVIEW |

Taiwan |

| Pneumatic element |

AIRTAC |

Taiwan |

| Switching power supply |

MEAN WELL |

Taiwan |

| Oil pump |

HYDROMAX |

Taiwan |

Warranty period – 3 years.

Production time – 30–50 days (depending on the package).

Supply rate – 20 units/month.