Equipment for manufacture of tubes with an option to use recycled cardboard or PE-coated — is an automated machine that performs the entire process of paper feeding, jointing and joint gluing, and assembly of finished products.

Technical specifications:

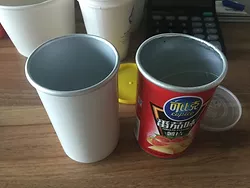

Cup sizes, mm:

Diameter: max 100

Height: max 220

Range of the material used, g/m2: 135-450

Gluing method: ultrasound and hot air system

Power: 12kW, 380V/220V, 60Hz

Air consumption: 0.4 m3/minute 0.5mPa

Weight: 3,4 tonnes

Dimensions of the machine assembling finished cups, mm: 2500х1800х1700

Output rate, pcs/minute: 70-80

Product advantages:

1. The Leister double hot air system guarantees the stability of heating.

2. Ultrasound gluing of the joint in a food box can glue cardboard with one-sided and double-sided PE-coating.

3. Panasonic transducers check each part of the article.

4. Automated system of lubricating mechanisms with oil.

5. Operation with a toothed gear guarantees a long service life of the equipment.

All major components used in this equipment are manufactured by well-known and reliable world manufactures, Panasonic, Siemens, Mitsubishi, Schneider, etc.

Model |

SMD-80D |

Country |

| PLC/Servo motor |

MITSUBISHI |

Japan |

| Inspection system/Photo electrical |

PANASONIC |

Japan |

| Hot air system |

LEISTER/BANKO |

Switzerland/CHINA |

| Transducer |

PANASONIC |

Japan |

| Contactor/Button/Termal protector |

SCHNEIDER |

France |

| Relay |

IDEC |

Japan |

| Temperature controller |

AUTONICS |

Korea |

| Needle bearing |

IKO |

Japan |

| Ultrasonic |

EVENGREEN |

Taiwan |

| Touch panel |

WEINVIEW |

Taiwan |

| Pneumatic element |

AIRTAC |

Taiwan |

| Switching power supply |

MEAN WELL |

Taiwan |

| Oil pump |

HYDROMAX |

Taiwan |

| Phase break and phase sequence protector |

C-LIN |

China |